產(chǎn)品中心

Products

Products / 產(chǎn)品中心

Products / 產(chǎn)品中心

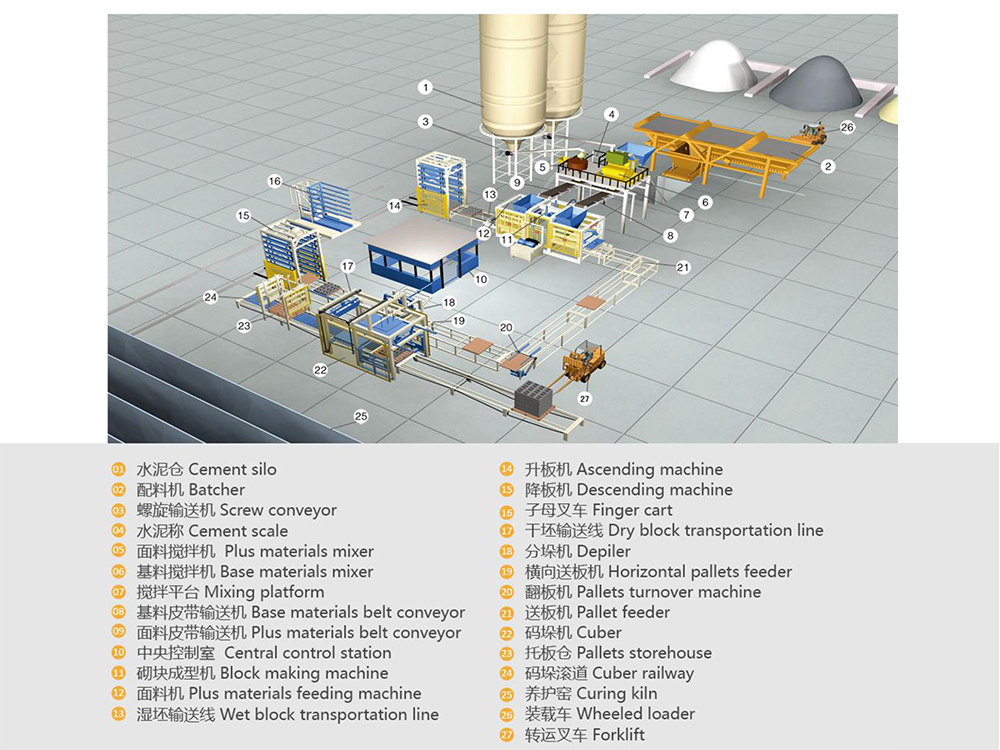

Brick Making Machine of Full Production Line

|

Equipment configuration

|

|||

|

(1)

|

Cement silo

|

(14)

|

Ascending machine

|

|

(2)

|

Batcher

|

(15)

|

Descinding machine

|

|

(3)

|

Screw conveyor

|

(16)

|

Finger cart

|

|

(4)

|

Cement Scale

|

(17)

|

Dry block transportation line

|

|

(5)

|

Plus material mixer

|

(18)

|

Depiler

|

|

(6)

|

Base material mixer

|

(19)

|

Horizontal pallets feeder

|

|

(7)

|

Mixing platform

|

(20)

|

Pallets turnover machine

|

|

(8)

|

Base materials belt conveyor

|

(21)

|

Pallet feeder

|

|

(9)

|

Plus materials belt conveyor

|

(22)

|

Cuber

|

|

(10)

|

Central control station

|

(23)

|

Pallets storehouse

|

|

(11)

|

Block making machine

|

(24)

|

Cuber railway

|

|

(12)

|

Plus materials feeding

|

(25)

|

Curing kiln

|

|

(13)

|

Wet block transportation line

|

(26)

|

Wheeled loader

|

|

|

|

(27)

|

Forklift

|

Advantages of using construction waste to make bricks:

(1) Bricks, stones, concrete and other wastes can be used for masonry mortar, plastering mortar and concrete cushion after being broken; After being finely crushed, the waste concrete blocks can be mixed with standard sand to form mortar fine aggregate for wall and ground plastering, roof mortar leveling layer, masonry mortar, making floor tiles, etc.

(2) Waste bricks are used as aggregates for building plates after being crushed. The manufacturing of partition board is not only light in weight, high in strength, but also sound insulation and small in expansion coefficient. The cost of the board is greatly reduced due to easy and cheap materials.

(3) After being crushed, the waste concrete blocks can be used as aggregates in the cast-in-situ concrete or prefabricated components and used for non bearing parts of buildings. This not only saves the construction funds, but also does not reduce the strength of the structure.

(4) The recycled bricks that can be produced include partition wall bricks, module bricks, pavement bricks, permeable bricks, thermal insulation bricks, grass planting bricks, sound screen barriers, etc. there are more than 100 kinds, and their performance indicators have reached or exceeded the relevant national standards.

Back

Back